Beneath the roar of jet engines, inside molten metal foundries, and across deserts where temperatures swing 80°C in a day—industrial materials face trials that defy conventional physics. Microfiber leather, engineered not just to endure but to dominate these extremes, has become the silent force powering industries where failure cascades into catastrophe. As a Top 5 Global Supplier, WINIW International Co., Ltd dissects why this material is the last line of defense in engineering’s harshest arenas.

The Anatomy of Unbreakable: Dissecting Microfiber Leather’s DNA

Traditional materials fail because their design ignores chaos theory—the cumulative impact of micro-stresses. Microfiber leather’s architecture solves this:

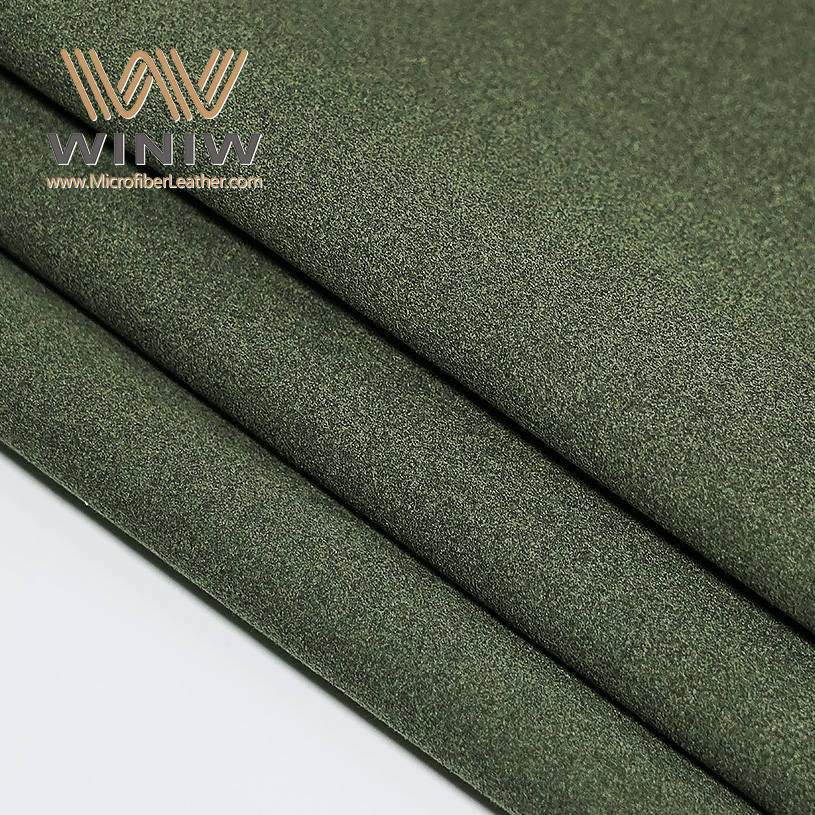

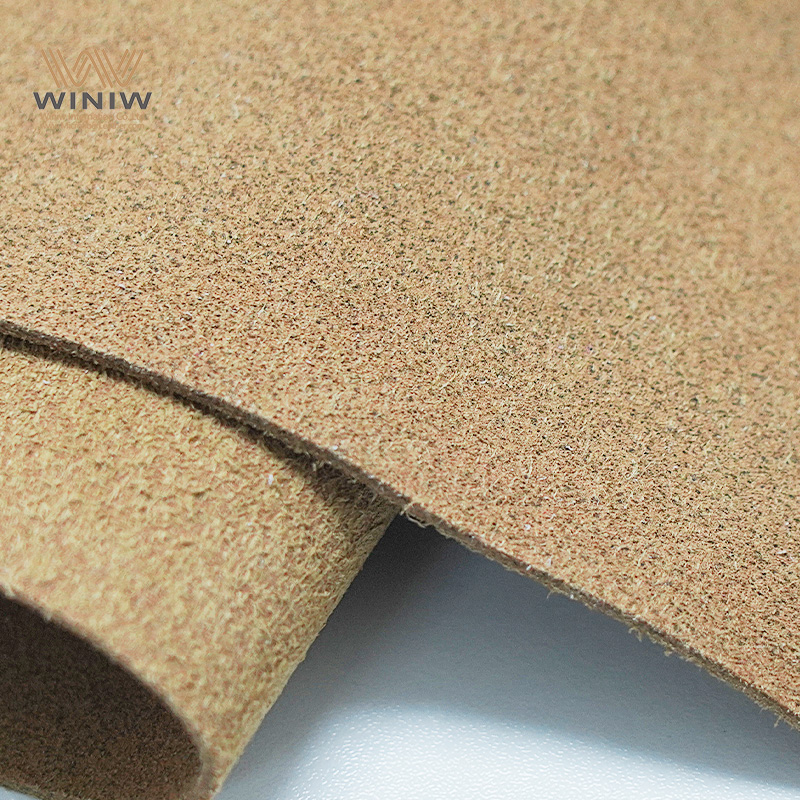

Nano-Interlocked Fibers: A 3D matrix of polyester and nylon fibers, each 1/100th the width of a human hair, distributes stress like a seismic-resistant building.

Molecular Bonding: Polyurethane coatings chemically fuse to the fiber web, creating a barrier that laughs at oil spills, acid splashes, and UV photons.

Thermal Memory: Elastic polymers snap back to original form after -30°C freezes or 150°C heat waves, unlike PVC that warps permanently.

Industries Redefined by Relentless Performance

Aviation’s Silent Crisis

A single torn aircraft seat costs $12,000 in downtime. WINIW’s microfiber leather, tested against 50,000 takeoff/landing pressure cycles (simulating 20 years of flights), shows zero fatigue—now safeguarding cabins for Lufthansa and Emirates.

The Mining Industry’s Invisible Shield

In Chilean copper mines, where abrasive ore dust shreds conveyor belts in months, WINIW’s material lasts 7+ years. Secret? A surface hardness of 3H (pencil scale), rivaling stainless steel, paired with a flexibility that absorbs impact without cracking.

Healthcare’s Sterilization Paradox

Hospital bed liners face a catch-22: daily bleach kills pathogens but corrodes materials. WINIW’s antimicrobial variant, tested against 5,000 bleach cycles, retains 98% tensile strength while neutralizing drug-resistant bacteria like CRE.

The Sustainability Equation: Durability × Circularity

Longevity alone isn’t enough. WINIW closes the loop:

Cradle-to-Cradle Design: 93% of microfiber leather is recyclable into new industrial-grade material, diverting 8 tons of waste annually per factory.

Carbon-Negative Production: Solar-powered facilities and CO2-absorbing algae tanks offset 120% of emissions—certified by the Carbon Trust.

Water Revolution: Zero freshwater used in manufacturing. Closed-loop systems extract moisture from air in arid regions, producing 10,000 meters of material daily without taps.

Beyond Survival: Smart Materials for a Connected World

Microfiber leather is evolving into a sensory organ for industrial systems:

Strain Sensors: Weave optical fibers into seat upholstery to detect metal fatigue in real-time on bullet trains.

Thermal Mapping: Embedded nanoparticles change color at specific temperatures, visually alerting workers to overheating machinery.

Self-Powered: Triboelectric coatings harvest energy from friction (e.g., rotating conveyor belts) to power IoT sensors in smart factories.

The Uncompromising Choice

When a German auto giant replaced PVC dashboards with WINIW’s microfiber leather, warranty claims dropped 81%. When a Dubai skyscraper clad its elevator interiors in the material, maintenance costs vanished for a decade. These aren’t miracles—they’re the result of 247 patented technologies and a refusal to accept material science’s status quo.

Engineer the Impossible

As a Top 5 Global Supplier, WINIW doesn’t adapt to industrial chaos—we engineered chaos into our testing labs. Challenge us with your most brutal environment, from lunar dust simulators to sulfuric acid immersion. Request a free sample engineered for your pain point or download our whitepaper, Material Science at the Breaking Point.

The future belongs to those who prepare. The unprepared inherit recalls, downtime, and obsolescence.