The development of artificial leather has been rich in categories, which can be mainly divided into three categories: PVC artificial leather, PU artificial leather and PU synthetic leather.

-PVC Artificial Leather

Made of polyvinyl chloride (PVC) resin, it simulates the texture and appearance of natural leather, but is more wear-resistant, water-resistant and ageing-resistant than natural leather. Due to its relatively low price, it is widely used in shoe materials, bags, furniture, car interiors and other fields. However, PVC artificial leather uses a large number of toxic additives, such as stabilisers and plasticisers, during processing, so it is less environmentally friendly.

PU Artificial Leather

PU artificial leather is a kind of artificial leather made of polyurethane resin, which is similar to genuine leather in appearance and touch, with soft texture, good elasticity, good durability and waterproof. Due to its excellent performance, PU artificial leather is widely used in the fields of clothing, shoes, bags, furniture and so on. Compared with PVC artificial leather, PU artificial leather is more environmentally friendly because it uses fewer additives in the production process and can be recycled.

-PU synthetic leather

PU synthetic leather is a kind of artificial leather coated with polyurethane resin and made of non-woven or woven fabric. Because of its smooth surface, light texture, good breathability and abrasion resistance, it is widely used in sports equipment, shoes, clothing and other fields. Compared with PVC artificial leather and PU artificial leather, PU synthetic leather is more environmentally friendly because its substrate can be recycled and fewer additives are used in the production process.

There are some differences in the application fields of these three kinds of artificial leather, PVC artificial leather is mainly used in products which need lower cost; PU artificial leather is widely used in the fields of garments and shoes; and PU synthetic leather is more suitable for the products which need high strength and high abrasion resistance, such as sports equipments and so on.

According to the different process and material, PU leather can also be divided into full water-based PU, microfibre leather and so on, they all have very outstanding advantages, in line with today's pursuit of environmental protection, aesthetics and other diversified market demand.

Water-based PU leather

Environmental protection, is made of water-based polyurethane resin and wet levelling agent, as well as other water-based auxiliaries, after a special water-based technology formulations and different fabric substrates water-based environmental protection dry hair line and related auxiliary environmental protection equipment processing made of

Five advantages.

1. Good abrasion and scratch resistance

Abrasion and scratch resistance of more than 100,000 times is not a problem, water-based polyurethane anti-abrasion and scratch resistance.

The anti-abrasion and scratch resistance of waterborne polyurethane originates from waterborne surface layer and auxiliary agent, which makes its anti-abrasion and scratch resistance grow exponentially, so the anti-abrasion and scratch resistance of waterborne polyurethane is more than 10 times higher than that of ordinary wet synthetic leather products.

2.Extra-long hydrolysis resistance

All water-based leather, compared with the traditional solvent wet process bass sofa leather, all use water-based polymer polyurethane material, with super durable hydrolysis resistance up to more than 8 years.

3. Skin-friendly and delicate touch

Full water-based leather has the same touch feeling as real leather, due to the unique hydrophilicity of water-based polyurethane and the excellent elasticity of the film, the surface of the leather made by it is more skin-friendly.

4. High colour fastness, yellowing resistance and light resistance.

Bright and transparent colour, excellent colour fixing, breathable and waterproof, easy to take care of.

5. Healthy and environmental protection

Water-based ecological sofa leather, from the bottom to the surface does not contain any organic solvents, the product is odourless, through the SGS test data 0 formaldehyde 0 toluene, in full compliance with EU environmental standards. It has good skin friendliness to human body, and is the most ecological and healthy product in the current synthetic leather products.

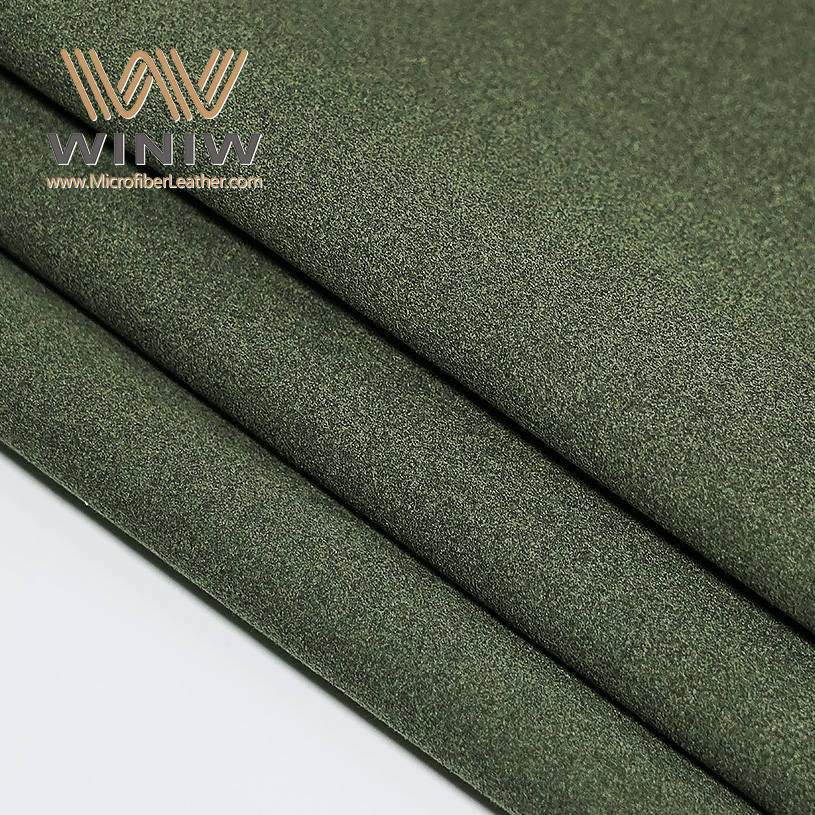

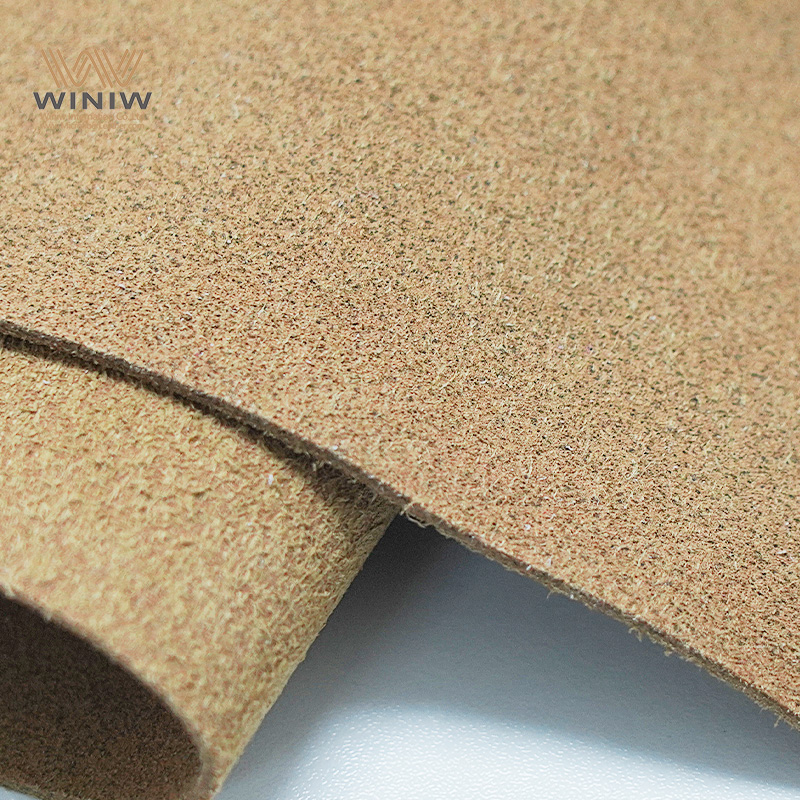

-Microfibre leather

The full name of microfibre leather is ‘microfibre reinforced leather’, which can be said to be the most high-tech artificial leather at present. High-quality microfibre leather combines many of the advantages of genuine leather, is stronger and more durable than genuine leather, is easy to process and has a high utilisation rate.

As the base cloth is made of microfibre, good elasticity, high strength, soft handfeel and good breathability, many physical properties of high-grade synthetic leather have exceeded that of natural leather, and the external surface has the characteristics of natural leather. From the industrial sense, that is suitable for modern scale production, and at the same time can protect the ecology, reduce environmental pollution, make full use of the non-natural resources, the surface has the original skin characteristics, microfibre leather can be said to be the ideal substitution of genuine leather.

-Advantages

1.Colour

Vividness and other aspects are better than natural leather

It has become an important direction for the development of contemporary synthetic leather

2. Extremely similar to genuine leather

The composition of fibre is only 1% of human hair, the cross-section is very close to genuine leather, the surface effect can be consistent with genuine leather.

3. Excellent performance

Tear resistance, tensile strength, abrasion resistance are beyond the leather, bending at room temperature up to 200,000 times without cracks, low-temperature bending 30,000 times without cracks.

Resistant to cold, acid and alkali without fading and hydrolysis resistance.

4. Light weight

Soft, smooth and excellent feel

5. High utilisation

Thickness of uniform and neat and no wear and tear of the cut surface, leather surface utilisation rate is higher than leather

6. Environmental protection and non-toxic

Does not contain eight heavy metals and other harmful substances to human beings, but also more to meet the needs of the vast majority of people, so microfibre in the artificial leather market has been more fire.

-Disadvantages

1. Bad air permeability, keeping the characteristics of cowhide, air permeability is still a gap compared with genuine leather.

2. High cost