I. Production Process Comparison

1. PVC (Polyvinyl Chloride) Artificial Leather Production Process

Basic process: Raw material mixing → Plasticization → Calendering or coating → Laminating with base fabric → Foaming (optional) → Embossing → Surface treatment → Cooling → Winding.

Key processes:

Calendering method: PVC material is rolled into a film using a multi-roller calender, then laminated with a base fabric.

Coating method: PVC paste is directly spread onto the base fabric and heated in an oven to form a solid film.

2. PU (Polyurethane) Artificial Leather Production Process

Basic process:

Wet process: Base fabric is dipped → Coated with PU slurry → Immersed in a coagulation bath (DMF-H₂O) → Washed → Dried → Surface-treated.

Dry process: Release paper is coated → Dried → Laminated with base fabric → Cured → Peeled off → Post-treated.

Key differences:Wet PU has good breathability, so it’s often used for high-end shoes and clothing.

Dry PU offers diverse surface effects, making it popular for bags and furniture.

3. TPU (Thermoplastic Polyurethane) Leather Production Process

Basic process:

Extrusion casting method: TPU is melted and extruded → Rolled into a film → Laminated with base fabric → Embossed → Cooled and shaped.

Blow molding method: TPU is melted and blown into a film → Combined with base material → Post-treated.

Coating method: TPU granules are dissolved, then coated → Dried and cured.

II. Performance Advantages and Disadvantages Analysis

PVC Artificial Leather

Lowest cost; raw materials are easy to obtain.

Mature production process; simple to process.

Good resistance to acids, alkalis, and weather.

Can be made into various colors and patterns.

Plasticizers easily migrate, causing hardening and brittleness.

Poor breathability; feels stiff.

Weak low-temperature performance (prone to cracking).

Poor environmental friendliness (contains chlorine; may have heavy metals).

Short service life (usually 2–3 years).

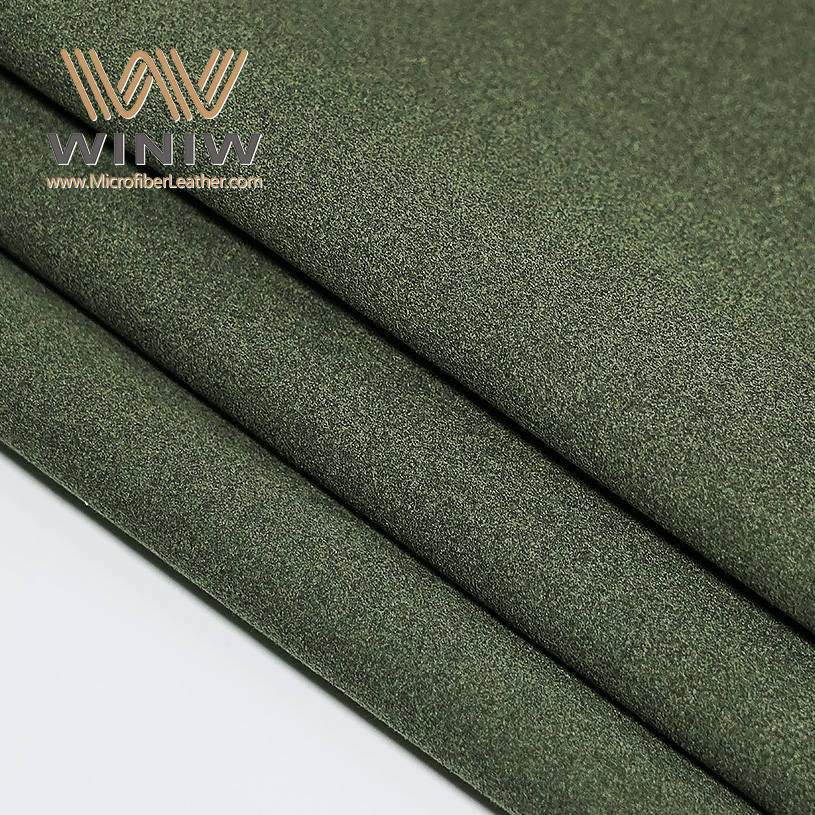

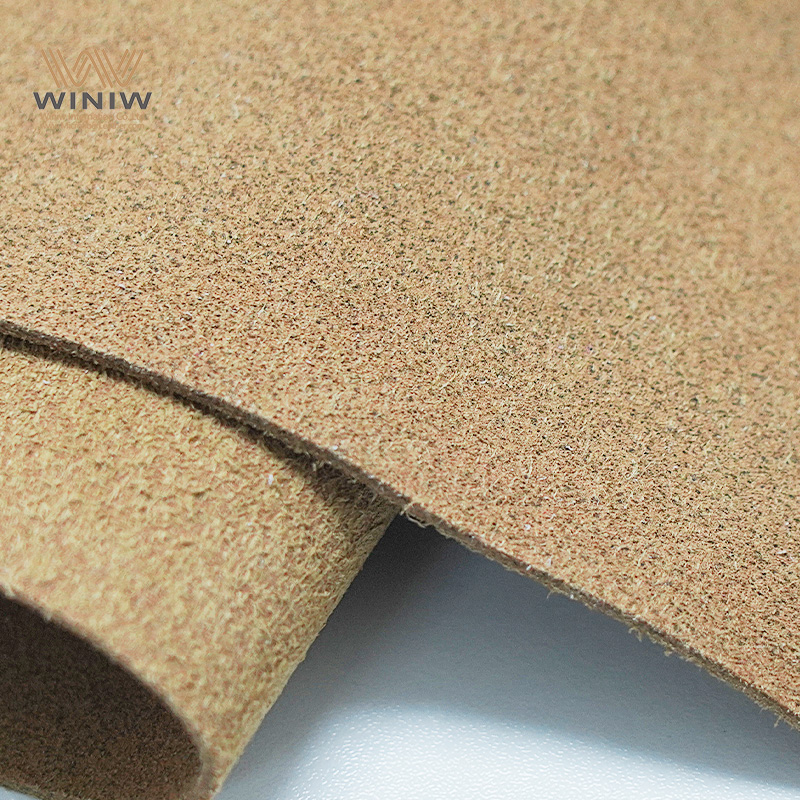

PU Artificial Leather

Feels closer to genuine leather: soft and elastic.

Better breathability and moisture permeability than PVC.

Good abrasion and flex resistance.

More biodegradable than PVC.

Diverse varieties (e.g., microfiber, suede-like).

Higher cost than PVC (about 30–50% more).

Complex production process (requires solvent recovery).

Poor hydrolysis resistance (especially polyester-based PU).

Prone to sticking at high temperatures and hardening at low temperatures.

Some products have DMF residues.

TPU Leather

Environmentally friendly and non-toxic (no plasticizers or halogens).

Excellent elasticity and abrasion resistance.

Good low-temperature performance (remains soft at −30℃).

Outstanding oil and hydrolysis resistance.

Can be hot-melt welded; 100% recyclable.

Highest raw material cost (1.5–2 times that of PU).

Narrow processing temperature range; difficult to control.

Slightly “plastic-like” feel; lower 仿真度 (simulation quality).

Higher cost for improved breathability versions.

Low market awareness.

III. Application Field Comparison

| Material | Main Application Fields | Typical Products |

|---|---|---|

| PVC | Low-end luggage, cover binding, car floor mats, simple furniture | Student backpacks, ID holders, cheap sofas |

| PU | Mid-to-high-end footwear, apparel, handbags, furniture, car interiors | Sneaker uppers, designer bags, business sofas |

| TPU | High-end outdoor gear, medical devices, electronic protectors | Hiking shoes, wetsuits, phone cases, medical braces |

IV. Environmental Performance Comparison

Production Process:

PVC: Chlorine-containing process; may produce dioxins.

PU: Requires DMF solvent recovery.

TPU: Mainly uses solvent-free processes.

Waste Disposal:

PVC: Difficult to degrade; incineration releases HCl.

PU: Partially biodegradable.

TPU: Thermoplastically recyclable; partially degradable.

Hazardous Substances:

PVC: May contain lead/cadmium stabilizers or phthalate plasticizers.

PU: May have DMF residues or amine catalysts.

TPU: Usually meets REACH and RoHS standards.

V. Development Trends

PVC: Shifting to lead-free calcium-zinc stabilizers and bio-based plasticizers.

PU: Water-based PU and solvent-free PU are key R&D focuses.

TPU: Market share grows as environmental demands rise.